The Invisco design improved the performance of the Australian hybrid that Edison tested and reported on in 2021. The hybrid tested then used a small motor to turn the turbine top to add powered air flow. That is very poor in higher static pressures.

My Invisco design added a big EC motor and a propeller so it pulls air in all expected static pressures.

SOUTHERN CALIFORNIA EDISON REPORTS THAT HYBRID VENTILATORS “GREATLY OUTPERFORMED BASELINE MODELS”

YOU GET THE BEST FREE GRAVITY AIR FLOW AND THE BEST POWERED AIR FLOW

Here is the comparison that shows what customers are most interested in – energy savings. The Australian rain hat offers better air flow than any other rooftop in America. AND your customer gets the best free gravity air flow!

The Australian rain hat makes the difference.

The reason the ventilator above is so much better is NOT my brilliance, it is because of the engineers at CSR Edmonds in North Ryde, Australia. THEY are the ones who thought up this brilliant vertical blade turbine rain hat. You can see below their original design. You can see they put a motor under the turbine to turn it to pull air. That design cannot pull air in static pressure above 0.11 inches of water. That is why the Invisco design has a motor and propeller in the throat.

Above is the Tornado’s EC motor and blade ……………………………………………..Above is the Aussie design with a ………………………………………………………………………………………………………………………motor turning the turbine.

SPECIFICATIONS

You have several models from which to choose based on the throat size and air flow. Below are the throat sizes and air flow.

- 12 inch

- 14 inch

- 20 inch

- 24 inch

- 30 inch

- 36 inch pulling 14,000 cfm

- 42 inch pulling 21,000 CFM

- 48 inch pulling 38,000 CFM

- 60 inch pulling 45,000 CFM

Here is one – the 36 inch TP900 – the entire specification is here – https://invisco.com/inventions/invisco-industrial-hybrid-rooftops/industrial-hybrid-rooftop-specs/

University of Washington in Seattle

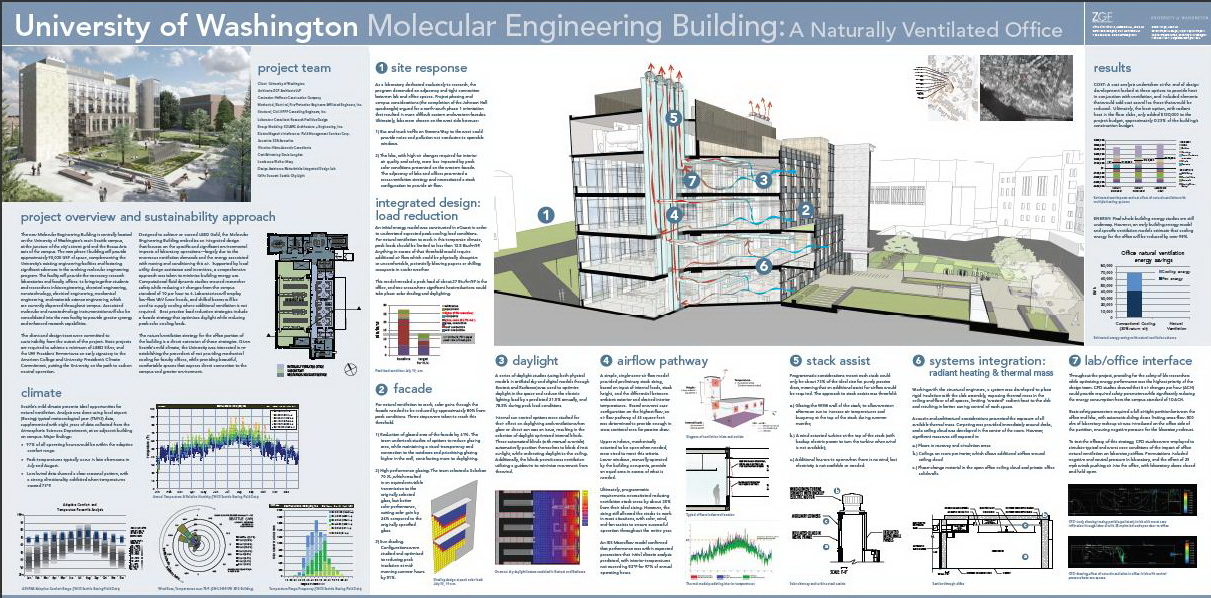

Zimmer Gunsul Frasca in Seattle WA worked with Affiliated Engineers Inc on the University of Washington’s new Molecular Engineering building built in 2013.

ZGF went to a lot of work to put many details of the design goals and implementation on a poster that is – in full size – 8 feet long! You can download it in pdf form here – University of Washington, Seattle

You can see the 8 ecoPOWER EP900s on top of the building. This image is a low resolution digital image. You can download the high resolution PDF using the link above.

AFFILIATED ENGINEERS USED THE HYBRID FOR STACK ASSIST

The purpose of this page is to describe Australian rooftop technology that was used by Affiliated Engineers in Seattle to design a new 4 story engineering building for the University of Washington in 2012. AEI went to Edmonds in Australia because none of the companies listed above had the excellent free gravity air flow that Edmonds has.

HERE IS THE DESIGN GOAL OF AFFILIATED ENGINEERS

This is the best example of the value of this Australian hybrid design- Affiliated Engineers working with ZimmerGunsulFrasca in Seattle chose Edmonds for passive draw in their stack – and since they could not quite meet the ideal draw they made use of the optional motorized air flow.

Here is Invisco’s industrial rooftop design in Los Angeles

James Shwe of Maroko & Shwe in Burbank California used this Tornado hybrid rooftop on a new gymnasium for Studio City in Los Angeles County. You can see the case study here – http://invisco.com/invisco-industrial-hybrid-rooftops/case-study-studio-city-gymnasium/

HEAT AND SMOKE VENT FOR WAREHOUSE ROOFTOPS HAS BEEN IMPROVED BY KURT SHAFER

I was asked to see if I could make a better heat and smoke ventilator. I found that most ventilators on the market use belt drives to isolate the motor from the hot air. . Invisco design is direct drive – no belts to melt. So there is no limit to time at 1000 degrees F.